Toggle Navigation

We find product engineers and designers frequently default to using aluminum alloy.While each casting alloy offers its own strategic benefits.

In the world of die casting, two materials dominate the conversation: aluminum alloys and zinc alloys (commonly Zamak series). Both offer unique

benefits, making them ideal for different types of applications. As engineers and procurement teams seek to balance performance, cost, and

manufacturability, choosing the right alloy is a strategic decision that impacts the entire product lifecycle.

In this article, we explore the strengths and trade-offs of aluminum and zinc die casting to help you make an informed choice for your next project.

Aluminum Die Casting: Lightweight Performance and Thermal Endurance

Aluminum alloys, such as A380 and ADC12, are widely used for their excellent strength-to-weight ratio and thermal resistance. Their benefits include:

1. Lightweight Design

Aluminum's low density (~2.7 g/cm³) makes it the preferred choice for applications requiring weight reduction, such as in automotive, aerospace, and

consumer electronics housings.

2. High-Temperature Tolerance

With a melting point of 660°C (1,221°F), aluminum parts are suitable for high-heat environments like engine compartments and lighting housings.

3. Large Part Capability

Aluminum is ideal for medium to large-sized castings, offering structural strength for load-bearing components.

4. Cost-Effective Material

Raw aluminum is less expensive than high-purity zinc, making it more economical for larger parts with higher material consumption.

5. Corrosion Resistance

Certain aluminum alloys provide natural resistance to corrosion, especially when treated with anodizing or powder coating, making them suitable for

outdoor and marine applications.

Zinc alloy Die Casting: Precision, Durability, and Efficiency

Zinc alloys (notably Zamak 3 and Zamak 5) are often underestimated, yet they bring outstanding value to small, high-precision, and decorative parts.

1. Superior Tool Life

Zinc dies typically last 10x longer than aluminum dies, with tooling capable of exceeding 1,000,000 shots. This drastically lowers long-term tooling costs.

2. Net-Shape Capability

Zamak alloys offer exceptional fluidity, enabling complex geometries and tight tolerances with minimal post-processing.

3. Faster Cycle Times

Zinc’s lower melting point (419.5°C / 787.2°F) and use in hot chamber machines allow for shorter cycles, translating to higher throughput and lower

processing costs.

4. Ideal for Decorative Finishes

Zinc’s low porosity provides a smooth surface finish, suitable for polishing, plating, or painting—making it a top choice for aesthetic components.

5. Thin-Wall Precision

Zinc can achieve thinner walls with excellent strength, allowing designers to reduce weight and material usage while maintaining structural integrity.

6. Exceptional Strength

Zinc alloys have higher tensile and yield strength than aluminum alloys, offering better performance under mechanical stress in small components.

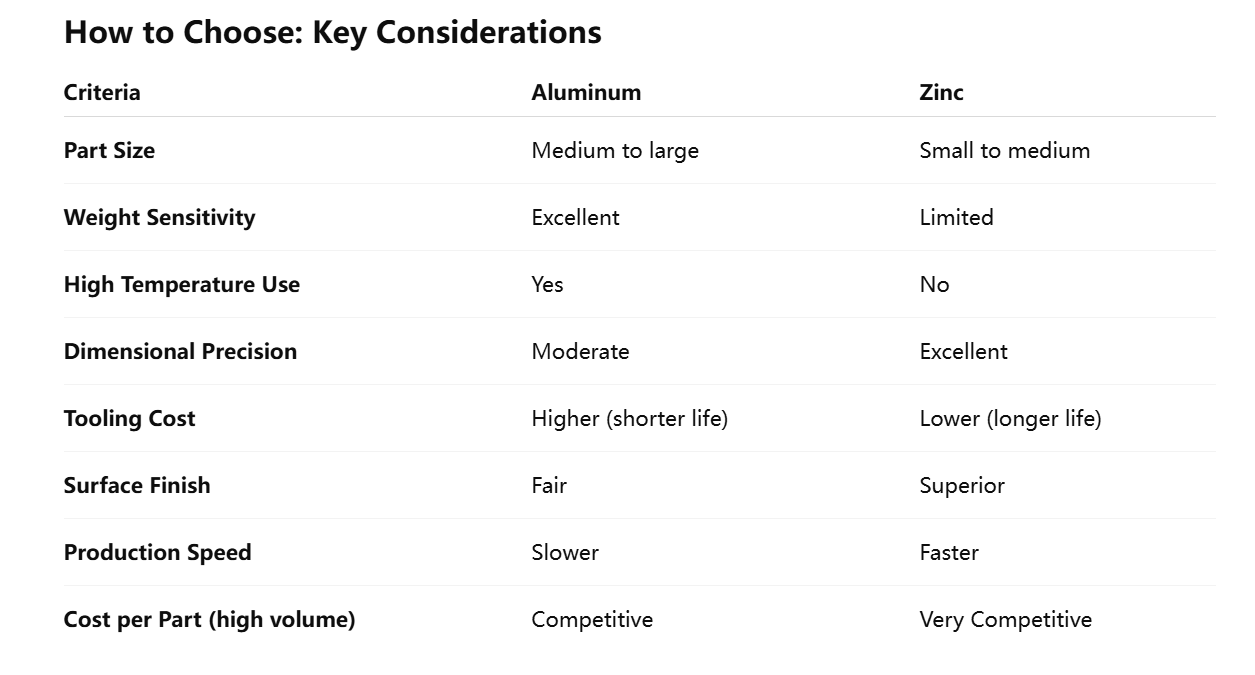

How to Choose: Key Considerations

Final Thoughts

There is no one-size-fits-all answer when it comes to die casting material selection. If your project involves lightweight structural parts, large component

sizes, or high-temperature environments, aluminum die casting is often the optimal choice.

However, if your design demands high precision, fine details, decorative finishing, and long tooling life—especially for small to medium parts—zinc die

casting offers unbeatable advantages in cost-efficiency and performance.