Toggle Navigation

In the dynamic world of manufacturing, the need for precision and efficiency has never been greater. At the forefront of this revolution stands the 5-axis CNC machine, a marvel of engineering that’s transforming the way industries design and produce complex parts. In a world where innovation is the key to success, 5-axis machining offers unmatched versatility and accuracy, elevating production to new heights.

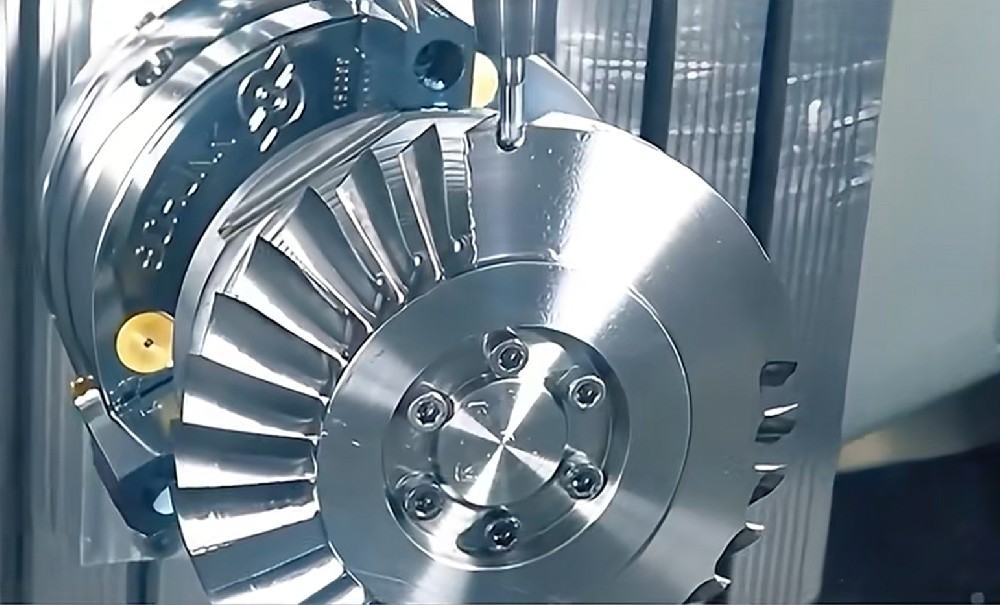

Unlike traditional 3-axis machines, which move in three linear directions (X, Y, and Z), a 5-axis CNC machine adds two rotational axes. This capability allows the cutting tool to approach the material from virtually any angle, unlocking unprecedented possibilities for creating complex geometries and intricate designs—all in a single setup.

This means manufacturers can produce components that were once thought impossible or required multiple setups, reducing time and increasing accuracy.

Precision and Complexity in One Go

The hallmark of 5-axis machining is its ability to achieve intricate shapes and contours with pinpoint accuracy. This is crucial for industries like aerospace, automotive, and medical, where the tiniest deviation can have significant consequences.

Fewer Setups, Greater Efficiency

Traditional machining often requires multiple setups to machine different features of a part. With 5-axis technology, a single setup is often sufficient, significantly reducing production time and the risk of human error.

Superior Surface Finishes

The tool’s ability to maintain optimal cutting angles minimizes vibrations, resulting in smoother finishes. This is especially important for parts like the wheel showcased in the video, where aesthetics and performance are equally critical.

Cost-Effectiveness

While the upfront investment in 5-axis machines is higher, the long-term benefits—reduced production time, minimal material wastage, and higher quality—make it a cost-effective choice for high-precision manufacturing.

The video demonstrates a striking example: a wheel being machined from a single block of material. The precision and speed at which the machine carves intricate spokes, curves, and contours highlight its capabilities. Every cut, every angle, and every rotation speaks to the meticulousness that only a 5-axis CNC machine can achieve.

This process doesn’t just produce a component; it creates a masterpiece that balances functionality with design, ideal for high-performance vehicles where every detail matters.

The versatility of 5-axis machining extends far beyond automotive wheels. From custom aerospace parts to surgical tools, this technology serves industries where precision and complexity are non-negotiable.

Aerospace: Perfect for creating lightweight, intricate components.

Medical: Essential for crafting implants and surgical instruments.

Automotive: Ideal for high-performance parts that combine durability and design.

In a competitive market, staying ahead requires leveraging advanced technologies. Partnering with a manufacturer equipped with 5-axis CNC machining capabilities ensures your parts are produced faster, with unparalleled precision, and at competitive costs.

The wheel in the video is more than just a product; it’s a testament to the capabilities of cutting-edge manufacturing. Imagine what this technology can do for your business.

Are you ready to take your manufacturing to the next level? Let’s explore how 5-axis CNC machining can revolutionize your production process. Whether you’re crafting complex components or aiming for the highest level of precision, we’re here to help.

Contact us today to discuss your project and see the difference precision machining can make.