Toggle Navigation

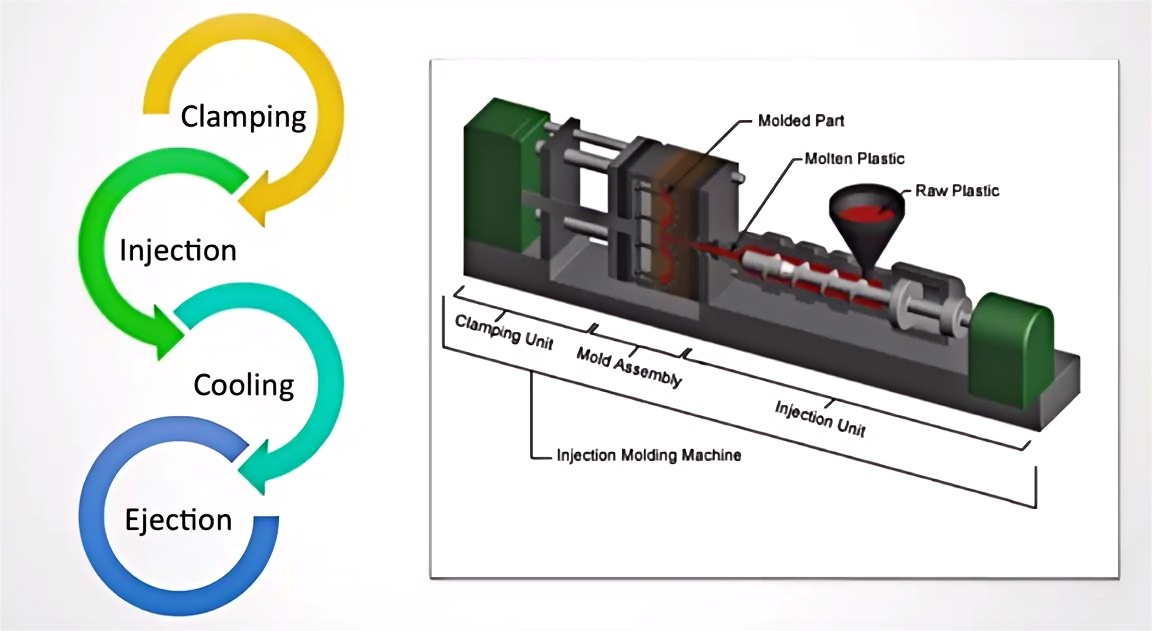

Plastic injection molding is a manufacturing process used to produce parts by injecting molten plastic material into a mold.

It is highly efficient for mass production of plastic components with complex shapes and is commonly used in industries like automotive, electronics, medical devices, and consumer products.

Clamping Phase: The core and the cavity are tightly closed and held together under high pressure by the clamping unit of the injection molding machine.

Injection Phase: Raw plastic materials (usually in pellet form) are melted and injected into a mold under high pressure.

Cooling Phase: Once the molten plastic fills the mold cavity, it is allowed to cool and solidify.

Ejection Phase: The mold is opened, and the newly formed part is ejected from the mold.

The advantages of the injection molding method are fast production speed, high efficiency, automated operation, a wide variety of colors, shapes from simple to complex,

sizes from large to small, and precise product size.

The product is easy to update and can be made into complex-shapeparts.

Injection molding is suitable for mass production and complex-shaped products and other molding processing fields.

High Efficiency for Mass Production: Once the initial mold is created, the injection molding process can produce large quantities of parts very quickly, making it highly efficient for mass production.

Design Flexibility: The molds can be designed to create highly complex shapes, including intricate internal details, thin walls, and different surface textures.

Consistent and Repeatable: Injection molding produces parts with consistent quality and precision. Each cycle results in identical parts, making it ideal for large production runs.

Minimal Waste: Excess material can be minimized during the molding process, and in many cases, leftover plastic from sprues or runners can be recycled and reused.

Factors affecting the quality of injection molding

1. Injection pressure: The existence of pressure is to overcome the resistance in the flow process of the melt, or conversely, the resistance in the flow

process needs to be offset by the pressure of the injection molding machine to ensure the smooth filling process.

2. Injection time: Reasonable injection time helps the melt to fill ideally, and it is of great significance to improve the surface quality of the product

and reduce the dimensional tolerance

3. Injection temperature: The injection temperature must be controlled within a certain range. If the temperature is too low, the melt is not plasticized

well, which affects the quality of molded part and increases the difficulty of the process; if the temperature is too high, the raw material is easy to

decompose.

Process cost: mold cost (high), unit cost (low)

Typical products: automotive plastic parts, consumer electronics plastic housings, etc.

Suitable for production: suitable for mass production

Quality: extremely high surface accuracy, extremely small shape error of products in the same batch

Speed: 30 seconds - 60 seconds / piece