Toggle Navigation

Sheet Metal Fabrication is a process by which sheet metal is formed into usable sheet metal parts and products. Sheet metal fabrication service

feature a variety of fabrication processes, such as laser cutting, bending, stamping, etc. All sheet metal fabrication processes seek to create high

quality, long-lasting parts and products, while reducing material and labor costs.

Here are some common techniques involved in sheet metal fabrication:

Laser Cutting: Laser cutting is a non-traditional machining method that uses an intensely focused, coherent stream of light called lasers

to cut through the material. This is a type of subtractive machining process where the material is continuously removed during the cutting process.

Bending: Applying pressure to bend the metal into specific angles or curves, deform a material to an angular shape.

It involves a bending machine that applies force to deform the metal along a predetermined straight line, ensuring precise and consistent results.

Through this method, the metal is expertly manipulated to achieve the desired form, maintaining structural integrity and meeting specific design requirements.

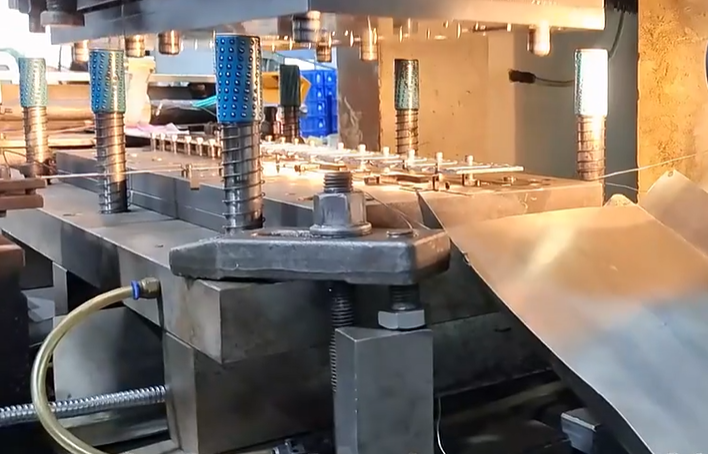

Stamping: Using dies to press patterns, holes, or shapes into the metal.

This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through

a series of stage.

Welding: Fusing two or more metal parts together using high heat.

Finishing: Applying surface treatments like powder coating or painting for aesthetic or corrosion-resistant properties.

Sheet metal fabrication can work with materials like steel, aluminum, copper, and other alloys, depending on the application.

Sheet metal fabrication offers several key advantages, It is widely used across various industries like construction, automotive, aerospace, and electronics due to its versatility, durability, and cost-effectiveness.

Strength and Longevity: Sheet metal is resistant to corrosion, wear, and environmental factors, especially when made from materials like stainless steel or aluminum. It offers a long service life, making it ideal for structural applications.

Multiple Applications: Sheet metal fabrication is flexible and can produce parts for industries such as automotive, aerospace, electronics, and construction. The process allows for creating custom components with varying thicknesses, shapes, and sizes.

Low Material Waste: Advanced techniques like laser cutting and CNC machining ensure precision with minimal material waste. Mass production can reduce costs per unit, making it an economical choice for both small and large-scale manufacturing.